Important! Instructions for operating a sandblasting machine right

Below are the important instructions for operating a sandblasting machine right, CAUTION, improper actions will lead to bad results.

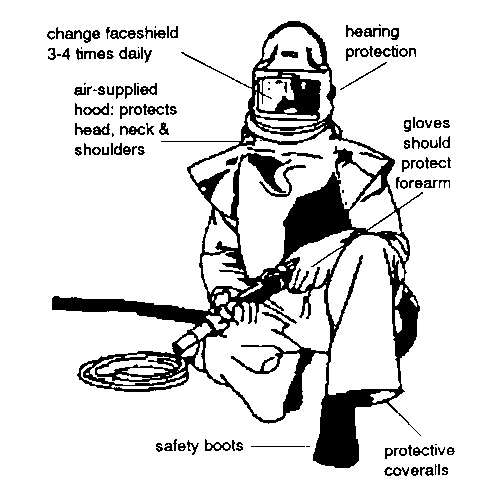

1. Before starting the sandblasting job, please put on complete protection equipments to protect yourself from accidental injury, including protection cloth, helmet and gloves, DO NOT expose your arms to the air while sandblasting. Besides, at least one partner is needed.

2. Air tank, pressure gauge and safety valve need to be verified at regular intervals. Air tank need to be cleaned up the dust every two weeks and filter inside the abrasive tank need to be checked up every month.

3. Double check if the vent pipe and window is completely sealed up or not. Start the dust removal equipment at lease five minutes in advance before sandblasting job. If the dust removal equipment fails working, DO NOT continue the sandblasting job.

4. Open the compressed air valve slowly, air pressure is not allowed to exceed 0.8MPa.

5. Choose suitable abrasive sand for different sandblasting job, normally between #10 and #12, and abrasive sand should stay dry.

6. When sandblasting job is on, unrelated person is forbidden to step close. When the cleaning and adjustment equipment is on,sandblasting job should be stopped immediately.

7. DO NOT use the compressed air to blow away the dust on the cloth or for kidding.

8. When sandblasting job is done, dust removal equipment should keep on working for another five minutes to remove the residue dust.

9. If somebody is inquired accidentally or equipment works abnormally,

DO NOT freak out, report to relevant department immediately.

Tags: Feng Blast News